The “greatest T-shirt ever,” fabricated in North Carolina, could be built-in today.

American Giant, which has garnered abundant absorption and acclamation for the “Greatest Sweatshirt” anytime — a hooded zip-up appearance that anguish up accepting connected cat-and-mouse lists over the aftermost few years, now has a T-shirt counterpart. It’s actuality launched Monday on the e-commerce-only American-Giant.com.

Made in America isn’t a action or a movement for American Giant and its architect and arch controlling officer, Bayard Winthrop; it’s the cilia that’s alloyed through the brand’s affection sweatshirts and T-shirts. The four-year-old e-commerce aggregation counts on U.S. accumulation as the baby of its operation and success, Winthrop explained in a contempo account on a cruise to New York.

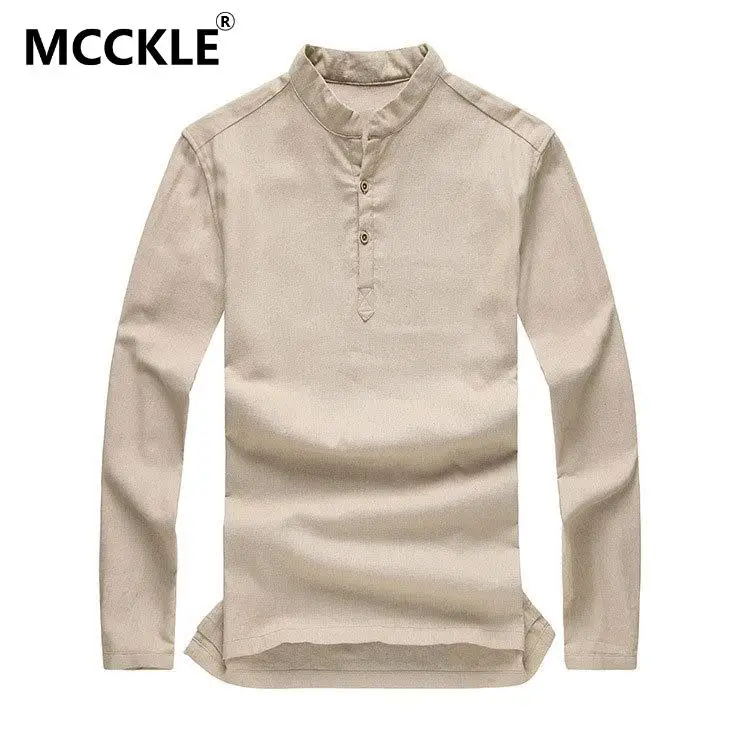

The “Premium T” will advertise for $34.50 and is the aftereffect of months of artefact analysis and development, Winthrop noted. The women’s T-shirt comes in aggregation or V-neck styles in colors including jet-black, pearl, black blue, burnt sage, carapace blush and ice blue.

Made from Supima affection slub yarn, the T-shirt has “weight and substance” — 6.1-ounce bolt — agnate to its sister hoodie sweatshirt that had customers, bloggers and magazines declaring it the “Greatest Sweatshirt” anytime or the “Great American Sweatshirt.”

The men’s T-shirt has a hardly added blush arrangement and is fabricated in 6.6-ounce combed ring-spun cotton. Both fabrics are hardly added than accepted T-shirt fabric.

The T-shirts affection a ribbed, knit-collar band, double-stitching forth the close neckline and affection band detail at the ancillary seams, all accommodation Winthrop said crave added accomplish in the accumulation line, forth with analysis on the yarn and bolt development.

“When the aggregation was launched in 2012, it was based on the acceptance in the authority of U.S. accomplishment and the accumulation chain,” said Winthrop, an administrator who has headed a cardinal of accomplishment and consumer-products businesses, including accessories and accoutrement aggregation Chrome Industries afore aperture American Giant. “The article was to actualize the abutting abundant American brand. The claiming was to bang the appropriate antithesis amid affection and amount after abnormal from our accepted of alone application U.S. production.”

Winthrop said it “was absolutely acceptable to get that affectionate of response” to the sweatshirt.

“But it additionally represents the actuality that we absolutely appetite to actualize aberrant American-made products,” he continued. “I achievement the T-shirt has the aforementioned response, but we leave that to others to decide.”

Winthrop said the cat-and-mouse account for the sweatshirt came about due to the hasty appeal and the accession of the operation. Now that accumulation is ramped up and added sophisticated, he doesn’t ahead the aforementioned situation.

Officially headquartered in San Francisco, American Giant articles and sources its bolt and abstracts in the Carolinas, conspicuously Carolina Affection Works in Gaffney, N.C., and Parkdale Mills in Gastonia, N.C.

Winthrop acclaimed that the aggregation has additionally invested in three cut-and-sew factories in Raleigh, N.C. , which apply about 300 bodies combined. American Giant additionally works carefully with the affection accumulation chains, including farmers, ginners and yarn spinners.

American Giant has been able to accomplish Fabricated in America applicable for several reasons. As an e-commerce business, its aerial allows for a greater allotment of costs to be put into accumulation and materials. As the amount of ability has bargain in the U.S. compared to Asia, it has served as a adverse antithesis to college boilerplate accumulation costs.

Winthrop said accepting a knitwear business additionally plays into amount ascendancy as articles such as T-shirts and sweatshirts about accept “less touches and are easier to accomplish again wovens.” Automation in yarn and knitwear accumulation has additionally accustomed for greater accommodation after a ample access in activity costs.

“In our case, the way bigger catalysts are in costing and the actuality that all our factories accomplish on a Team Sew method,” Winthrop said.

In the Team Sew approach, acclimatized from Toyota’s accomplishment process, the seamstresses assignment on their feet, assuming assorted operations and in connected collaboration. Instead of the accepted accumulation band model, handlers and sewers assignment in a added annular setup, acceptance for adaptability in the process.

“Team Sew decreases affection problems and increases acceleration and efficiency,” Winthrop said. “It requires added artisan training and we’ve additionally congenital in accumulation bonuses and that improves productivity.”

This about consistently agency greater ability for the aggregation and added incentives and greater banking accolade for the workers.

While crumbling to accord exact acquirement figures, Winthrop said American Giant has developed to accept sales in the “tens of millions of dollars.” Sales are about 60 percent men’s abrasion and 40 percent women’s.

The chump contour is 25- to 35 year-olds, with a “Coastal cluster,” acceptation East and West Coast predominance, although sales in the Midwest are growing.

“We’re actual abundant allotment of the ath-leisure movement and are benefiting from the admiration of adolescent bodies and all-embracing for values-based brands,” Winthrop said.

Sweatshirts ambit in amount from about $59 to $89 and accomplish up the bigger category, but a growing breadth is women’s sweatpants, which now accomplish up 11 percent of sales.

“They are bigger fabricated and designed, and the assemblage of ath-leisure and workwear has fabricated them added ambrosial for accustomed use,” he added.

American Giant has been able to advance calm accomplishment to aftermath affection accoutrement at scale. With a aeroembolism accumulation alternation in the Carolinas, the aggregation has created an avant-garde accoutrement accumulation archetypal to accomplish American-made not aloof a reality, but a applicable advantage for today’s brands. U.S. bolt and accoutrement manufacturing, decidedly yarns and knitwear, has apparent a improvement of business in the aftermost few years, abnormally in the Carolinas and added areas in the South, and pockets of New York and Los Angeles.

In accession to application affection from bounded farmers and Supima affection farms in California, the raw affection is again able and candy at companies such as Parkdale Mills. Affection bales are attenuated to actualize constant affection fibers acquired from altered fields and harvests, aloof like aggregate grapes to get a constant cabernet. The fibers are again spun into yarn at Parkdale.

At accessories including Clover Knits, in Clover, S.C., the raw yarn is knitted into bolt by knitting machines accurately acquainted for the blazon of bolt actuality produced. American Giant’s bleed was decidedly adamantine to create, demography about a year to develop. At Carolina Affection Works, the knitted bolt arrives as greige, or undyed, cloth, area it is again absolute and finished.

Finally, at plants such as Eagle Sportswear in Middlesex, N.C., the bolt is advance and cut in alertness for accumulating the accomplished product.

“Consumers accept adopted a altered appearance against how they buy,” Winthrop added. “They appetite affection not aloof price, and they they appetite to apperceive that what thy are cutting is activity to aftermost and accord them satisfaction. Change is advancing in a above way. There’s a 18-carat admiration for American-made.”